Explosives and Explosions Blog 1 by Eric Eaton

Explosives used in coal mines

1627 First recorded use of black powder for rock blasting (Hungary).

1670 Black powder use spreads to tin mines of Cornwall England by German miners

Explosives are used in underground mines and quarries to break coal and other rocks. An explosive is a solid or a liquid substance or mixture of substances which change themselves instantaneously into a large volume of gases at high temperature and pressure when a flame, heat or sudden shock (detonation) is applied to it

Are explosives required for underground coal mines?

Specially designed explosives and detonators are required for use in underground coal mines. PERMITTED EXPLOSIVES Only those explosives, which are included in the official list of authorised explosives issued by the Chief Controller of Explosives, may be used for blasting in mines. Only on passing the tests in an explosive approved as a “permitted” explosive. There are 3 types of permitted explosives, each group being designed for a particular type of operation to give maximum safety. P-1Type Permitted Explosives: These explosives can be used for drifting or ripping and simultaneously firing in an undercut/middle-cut/overcut and in depillaring faces, in coal seams of first degree of gassiness. P-3Type Permitted Explosives: These are Equivalent-to- Sheathed Explosives used for drifting or ripping and simultaneously firing an undercut/middlecut/overcut and in depillaring faces, in coal seams of first degree of gassiness. P-5Type Permitted Explosives: These are special type of explosives with a higher degree of intrinsic safety against all types of likely hazards in delay blasting in coal and specially designed for Solid Blasting in conjunction with non- incendive copper short delay detonators.

Firing the Supple Gate rip

Charge-man makes sure no loose stone on ripping lip.

First job Set Bull bar 4feet behind last bull bar.

Second job set side breaking off bars at sides.

Third job pull all belting forward up to bull bar. (belt makes easier shovelling than off normal floor)

Forth job remove first bull bar with a bit of rope or shot-firing cable placed in the props. (Watch out for loose stone falling as the bull bar is removed)

Fifth job, Charge-man and helper bore 6 bottom holes in the stone, with borer and 4ft drill rod, making sure to put a new bit in the drill rod to make boring easier, (six holes is to make sure the stone is small better for shovelling).

Sixth job, tell Deputy to make up 6 8oze sticks of powder,( a bag of gun powder is made up of 8 and 4ozes sticks of gun powder.)

(Deputy inserts detonators in six 8ozes sticks of gun powder) Safety, you cannot carry gun powder and detonators’ together because they might explode, so men carry the gun powder and the Deputies carried the detonators.

Seventh job, Deputy and charge-man insert gun powder sticks with detonators into the six holes and ram them with clay taking care not to break the wires from the detonators.

Eighth job, couple all the wires together making sure there is a circuit and then couple the wires up to the shot-firing cable. (shot-firing cable is run out down the gate for about 30-40 metres a safe distance from the shots to be fired).

Ninth job, Deputy checks for gas around the lip

Tenth Job, tell men to go to a safe place onto the face as the shots are going to be fired.

Eleventh Job, Deputy connects shot firing cable to battery.

Twelfth Job, Deputy checks that there is no one around the ripping lip.

Thirteenth Job. Deputy shouts Fire, turns the key on the battery and presses the button, smoke and awful smell comes down the gate.

Fourteenth Job, Deputy checks the shots have fired, informs the men everything alright.

Fifteenth job, Charge-man trims up the lip of all loose stone.

Sixteenth Job, Charge-man and helper put three holes in the middle of the lip and two in the top, standing on the stone from the first shots. (less holes to make bigger stone for packs)

Seventeenth Job, Charge-man tells Deputy to make 5 more 8oze sticks of gun powder up.

Eighteenth Job, Deputy and charge-man put the gun powder with the detonators’ in to the hole and stem with clay being careful not to break any wires.

Nineteenth, Couple all the wires into a circuit and then couple the shot firing cable to them.

Twentieth job, Deputy checks for gas around the lip.

Twenty-first job, tell all men to go to a safe place onto the coal face as shots are going to be fired.

Twenty second job, accompany Deputy down the gate.

Twenty third Job, Deputy connects shot firing cable to battery.

Twenty fourth Job, Deputy checks that there is no one around the ripping lip.

Twenty fifth Job, Deputy shouts Fire, turns the key on the battery and presses the button, smoke and awful smell comes down the gate.

Twenty sixth Job, Deputy checks the shots have fired, informs the men everything alright.

Twenty seventh Job, Charge-man trims up the lip of all loose stone and makes safe.

Twenty eighth Job, Charge-man and helper move the horse heads forward.

Twenty ninth Job, Charge-man and helper fetch the ring bow from down the gate and place it on the horse heads, chock it up put struts on and board it in

Snap time 20 minutes.

Thirtieth job, clean up all the stone putting into packs., Charge-man and helper put tight side pack on.

Thirty first Job, Charge-man and helper build scaffolding, while rest of team fetch ring legs, struts and boards from down the gate.

Thirty second Job Couple ring legs to ring bow with ring plates and bolts, strut them and board them in.

“This would be setting one ring on day shift; it would be two rings so double the work on nights.”

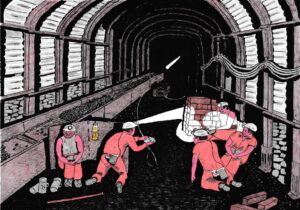

Brian Morley, Mining Artist, describes the following scene, when the rippers were ready for firing the shots, in his Exhibition Catalogue which we hope will to be on sale soon.